Making one of our custom orthotics is an art and a science – the process takes five days, uses a variety of state-of-the-art machinery, and requires the time and expertise of several custom orthotic technicians.

Here’s how they’re made:

Making one of our custom orthotics is an art and a science – the process takes five days, uses a variety of state-of-the-art machinery, and requires the time and expertise of several custom orthotic technicians.

Here’s how they’re made:

1

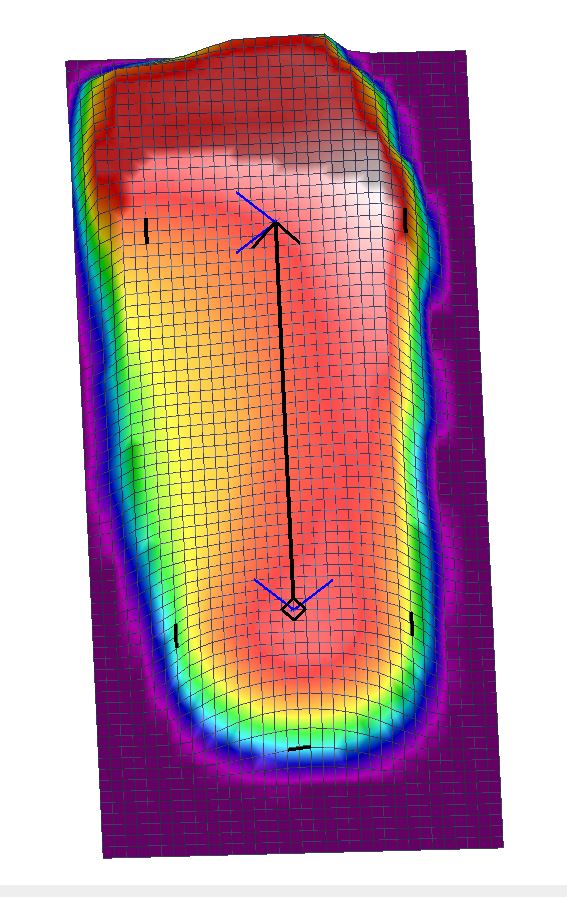

Every MojoFeet Custom Orthotic begins with a 3D scan of a customer’s foot or feet in the corrective position. Scans are obtained using one of two methods. First, a scan can be obtained by having a health professional create a mold of the foot using a foam. The mold is then mailed to us, and we scan the mold to create a 3D image. The second method is creating a 3D image from the outset – using a scanning device, such as our patented Mojo Matrix digital imaging system, to create a 3D image of the foot. Once the scan file is created, it is transmitted to us electronically, and we can begin with the second step in the process.

2

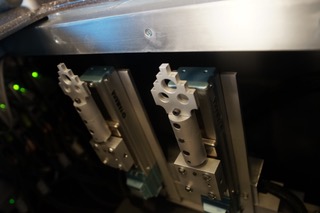

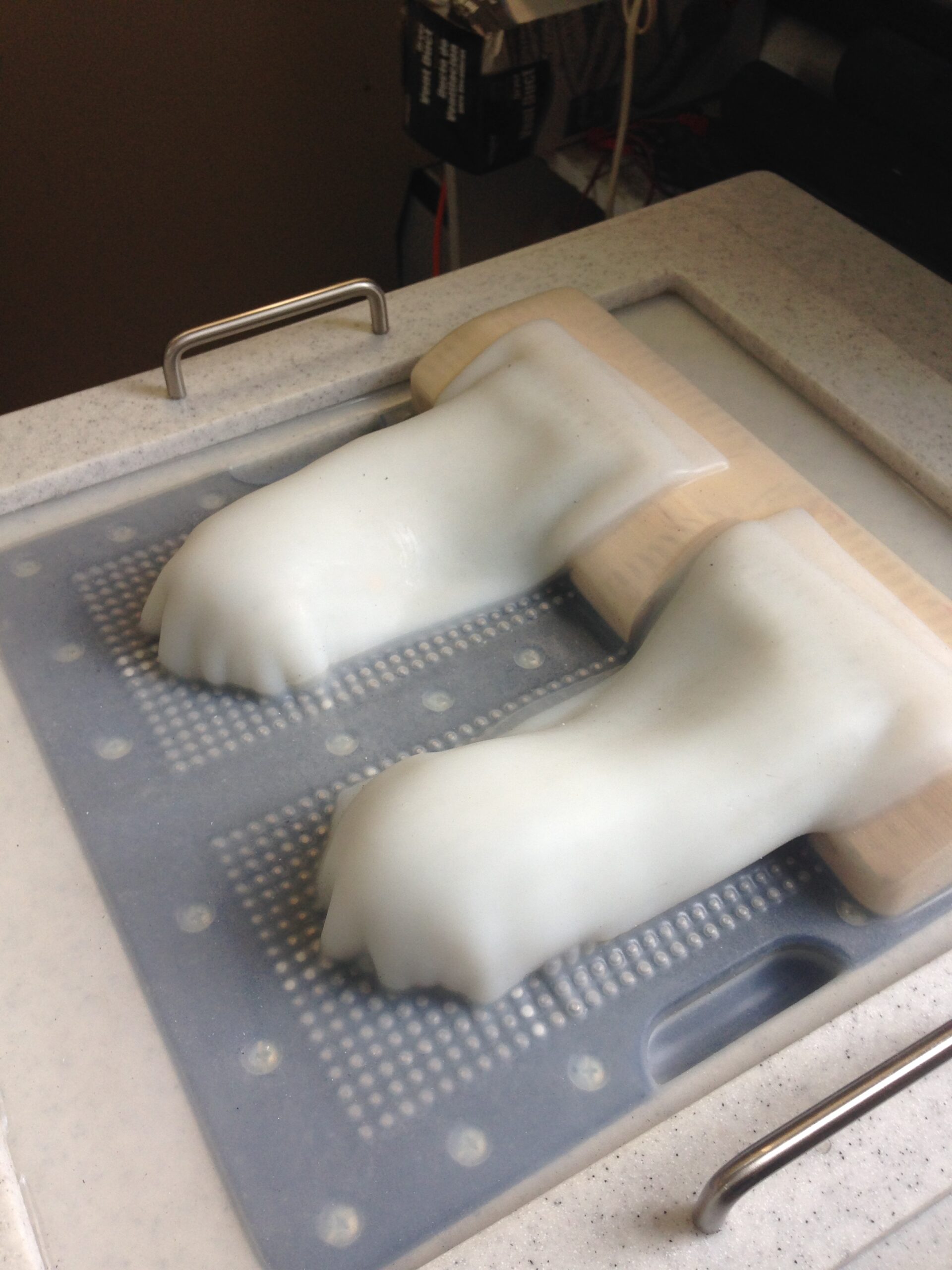

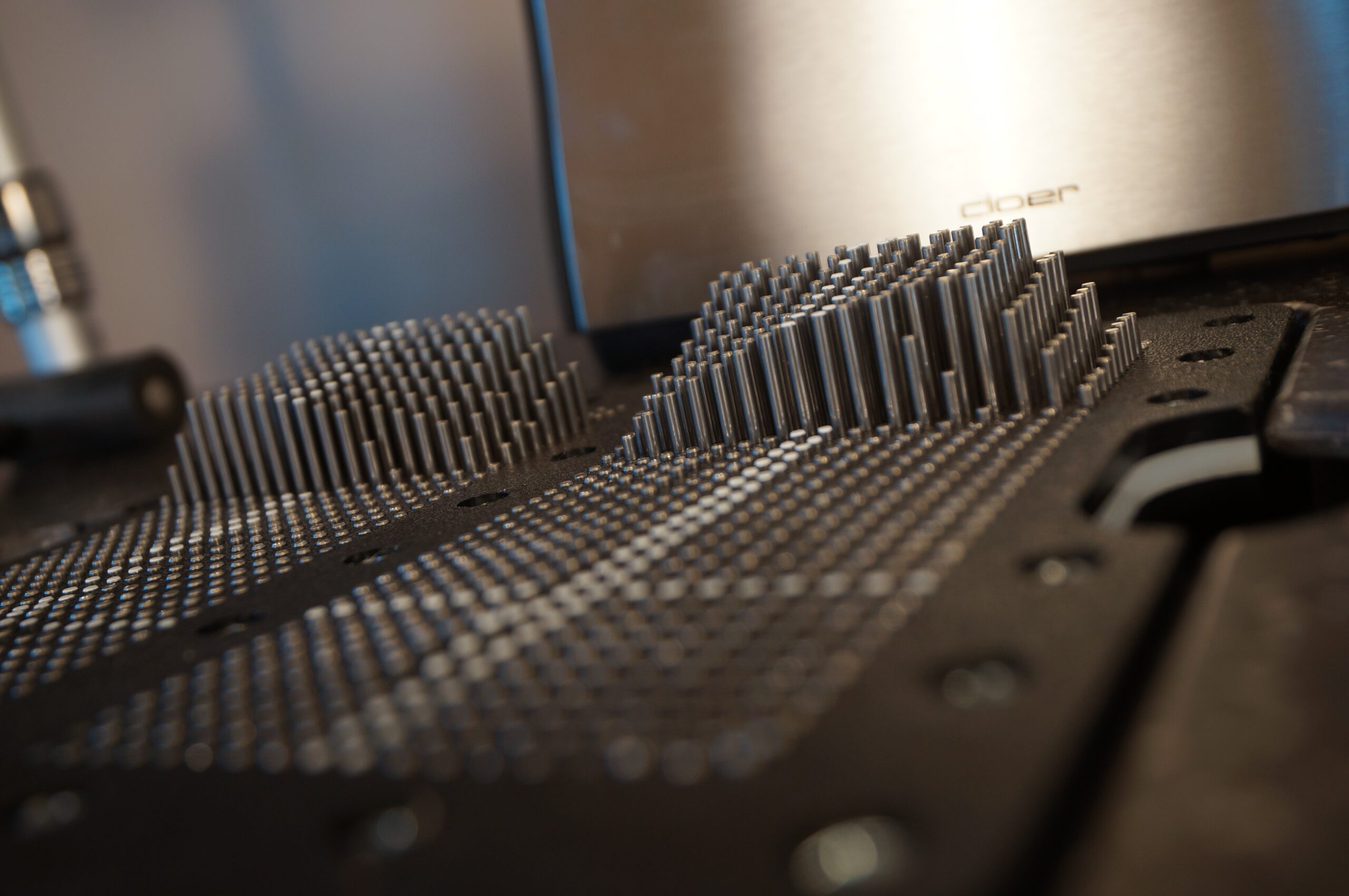

With the 3D scan in hand, we use a pin array device that physically recreates the precise form of the foot as it was captured in the health care provider’s office. Once the pins are in place, we thermal form a high-grade plastic (high-density, high-molecular-weight polyethylene) over the form of the foot and use a vacuum press to form the plastic to the exact shape of the mold.

3

Once the rough core has been created, our technicians begin shaping the orthotic using a series of saws and grinders, forming the orthotic to the exact shape needed to fit a person’s foot. We do additional grinding to achieve a specific thickness of the plastic core.

4

Orthotics are meant to move. They control pronation (they do not stop pronation) by flexing and applying pressure to parts of the foot to correct biomechanical issues so you can walk, stand or run in a more natural way. Because they are meant for correction, the way an orthotic moves and flexes is extremely important. We tune our orthotics by grinding them and flexing the arch to achieve a specific flexibility, which we gauge using precision measuring instruments and our technician’s expertise. A properly tuned orthotic takes into account specifications such as a person’s foot ailments, weight, pronation control requirements, and goals for health, fitness and lifestyle. Once the custom orthotic core is properly tuned, it is buffed to ensure a smooth finish and soft edges.

5

With the core built and properly tuned, it is time to add the textile material covering. Textiles are available in a variety of options, and are selected based on clinical need, as well as comfort, durability and color. All of our custom orthotics use high-quality materials such as high-rebound EVA, D3O® smart foam, Ultrasuede®, anti-microbial BioSkin™ or the ballistic nylon Cordura®. They are also highly durable, have low coefficient friction, and are smooth to the touch, so they don’t cause blisters or ruin your socks. Once the textile is selected, the material is cut to specification and glued in place.

6

Every custom orthotic we build goes through a quality check where our technicians review the entire orthotic from top to bottom to ensure it functions to the proper level of correction. Once we’re satisfied with our work, we ship the orthotic to your health care provider’s office using FedEx’s two-day shipping option.

And that’s how MojoFeet Custom Orthotics are made!

If you’re interested in learning more about MojoFeet Custom Orthotics, a member of our sales staff would be happy to assist you. Please call or email us today at 1-855-MOJO-LAB (665-6522) or info@mojofeet.com, or fill in the form on our contact page.

Contact Us© Copyright 2026 MojoFeet. All Rights Reserved. Website by Sryde Digital Marketing